Introduction

Sometime back I thought about making a wheelchair ventilation system that could be used to help alleviate an overheating

problem. The area most effected is the lower back as one might expect. The molded chair is covered in 1/2 inch thick foam,

a cover and seat cushion.

The cover a few millimeters thick always air to pass through it.

And cover removed.

And cover removed.

THE PLAN

Build a device capable of ...

a) Drawing air out of the chair.

b) Ably to run for a week (sitting time) on one battery charge.

c) Fully automatic in operation.

Initially a 12 volt fish tank air pump was a candidate but the current draw was too high.

Next, the use of a 12 volt PC fan was considered. I wasn't sure that the fan would be strong enough,

but at only 80MA current draw it was worth a try. Before starting on any electrics I rigged up the basic unit and put it on

test for a week.

Good news, no sign of over heating, everything bone dry. It would seem that a small air flow over the period of a day is enough.

True, it's not summer yet but then even indoors during winter it's been a problem, so far so good ... on with the

electrical work.

THE PARTS

Here's a list of the main components used.

a) Project Box to house the fan and electrics.

b) 80mm 12 volt PC Fan.

c) 80mm Fan Grills.

d) Circuit to switch fan on/off dependent on temperature.

e) Circuit to warn of low battery charge.

f) Flexible hose to draw air out of the chair.

g) Connectors to connect pipe to box and chair.

BUILDING

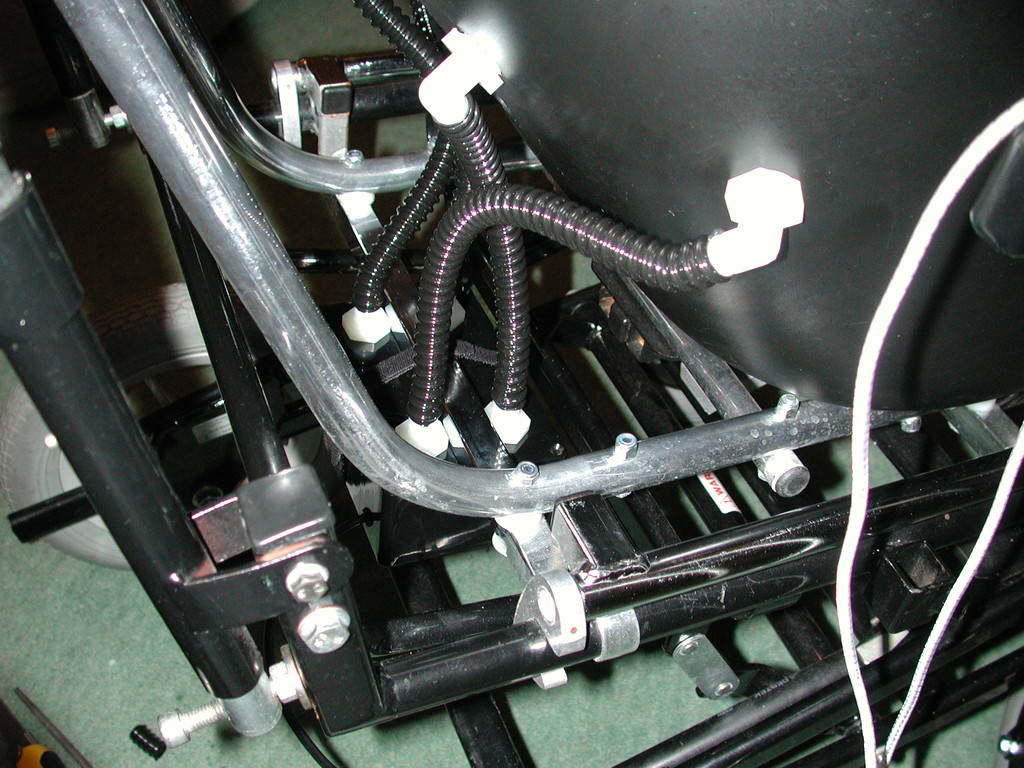

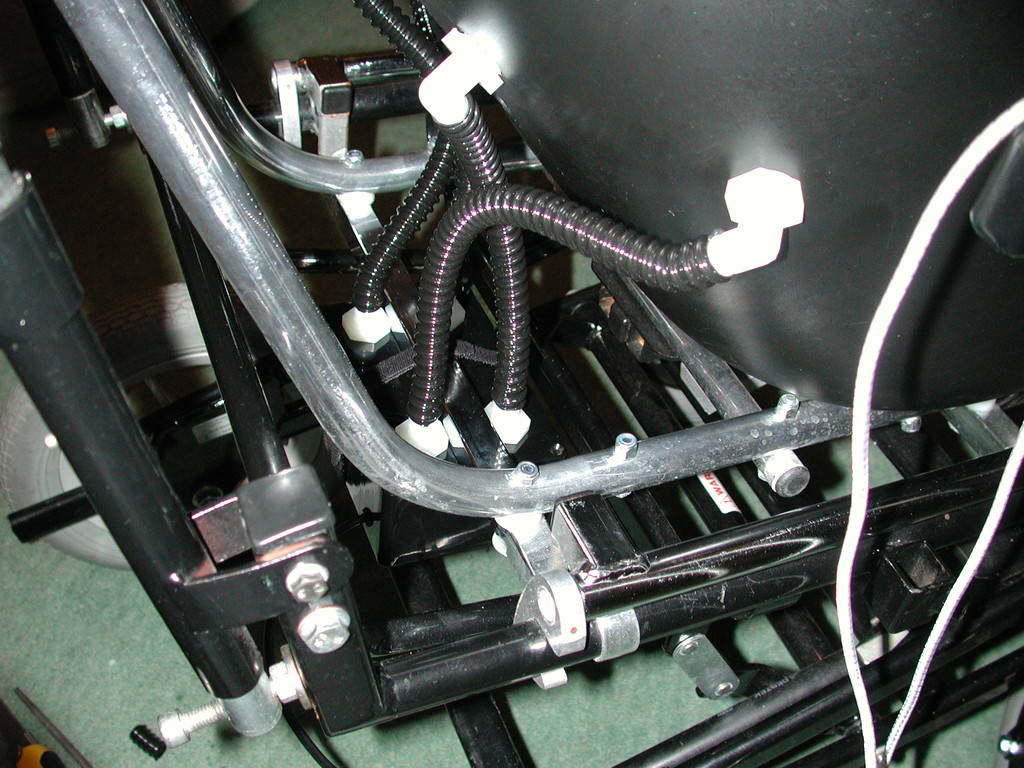

Four 20mm holes drilled in the top of the box to accommodate the pipe connectors and tubing. The box I used however will

accommodated six holes. But to start with I just used four.

THE PLAN

Build a device capable of ...

a) Drawing air out of the chair.

b) Ably to run for a week (sitting time) on one battery charge.

c) Fully automatic in operation.

Initially a 12 volt fish tank air pump was a candidate but the current draw was too high.

Next, the use of a 12 volt PC fan was considered. I wasn't sure that the fan would be strong enough,

but at only 80MA current draw it was worth a try. Before starting on any electrics I rigged up the basic unit and put it on

test for a week.

Good news, no sign of over heating, everything bone dry. It would seem that a small air flow over the period of a day is enough.

True, it's not summer yet but then even indoors during winter it's been a problem, so far so good ... on with the

electrical work.

THE PARTS

Here's a list of the main components used.

a) Project Box to house the fan and electrics.

b) 80mm 12 volt PC Fan.

c) 80mm Fan Grills.

d) Circuit to switch fan on/off dependent on temperature.

e) Circuit to warn of low battery charge.

f) Flexible hose to draw air out of the chair.

g) Connectors to connect pipe to box and chair.

BUILDING

Four 20mm holes drilled in the top of the box to accommodate the pipe connectors and tubing. The box I used however will

accommodated six holes. But to start with I just used four.

Straight Connectors

All connectors came from the aquarium shop but are probably available elsewhere. The plastic nut is used

in the average toilet cistern.

Straight Connectors

All connectors came from the aquarium shop but are probably available elsewhere. The plastic nut is used

in the average toilet cistern.

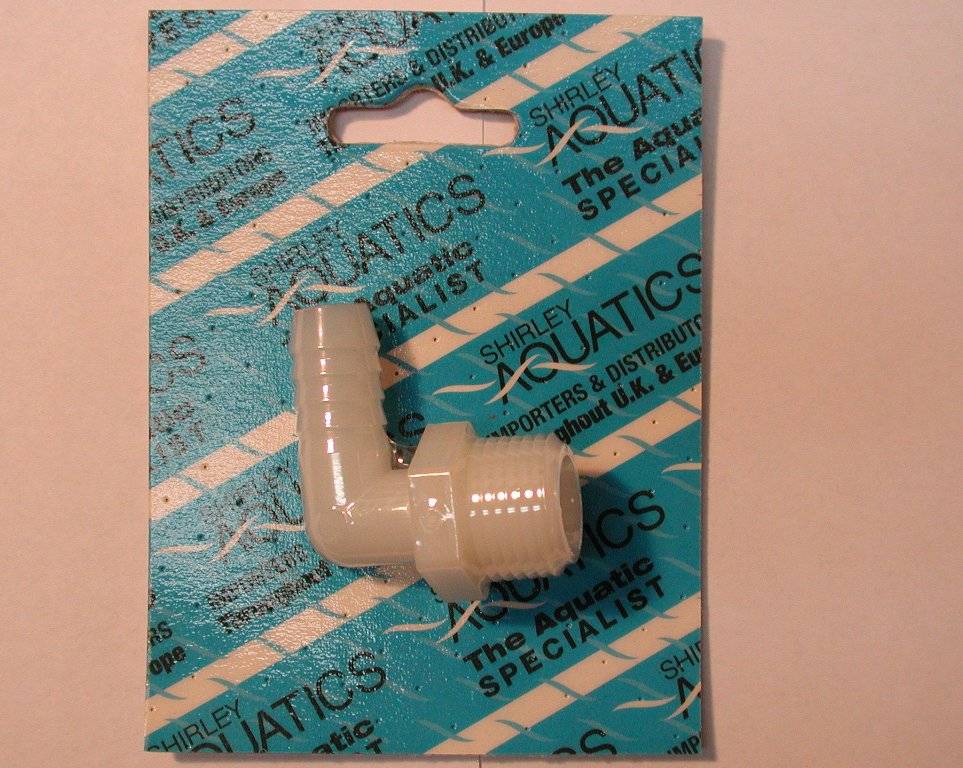

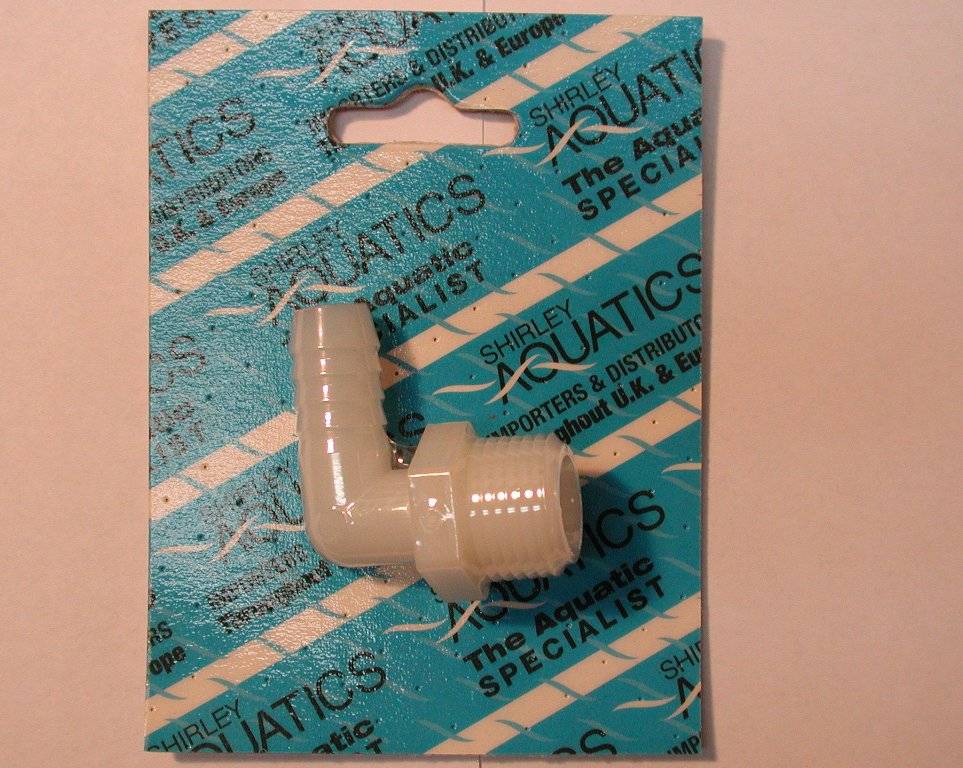

90 Degree Connectors

The vent holes already in the chair were the correct size (20mm) and the connectors screwed easily into the chair and are

surprisingly airtight.

90 Degree Connectors

The vent holes already in the chair were the correct size (20mm) and the connectors screwed easily into the chair and are

surprisingly airtight.

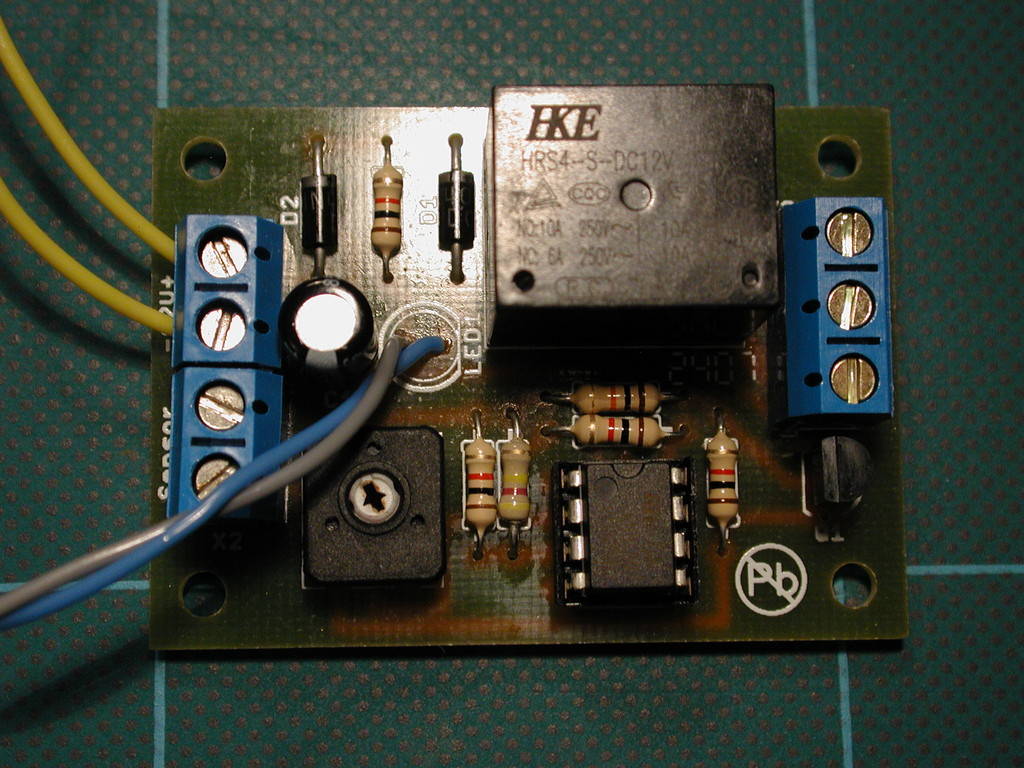

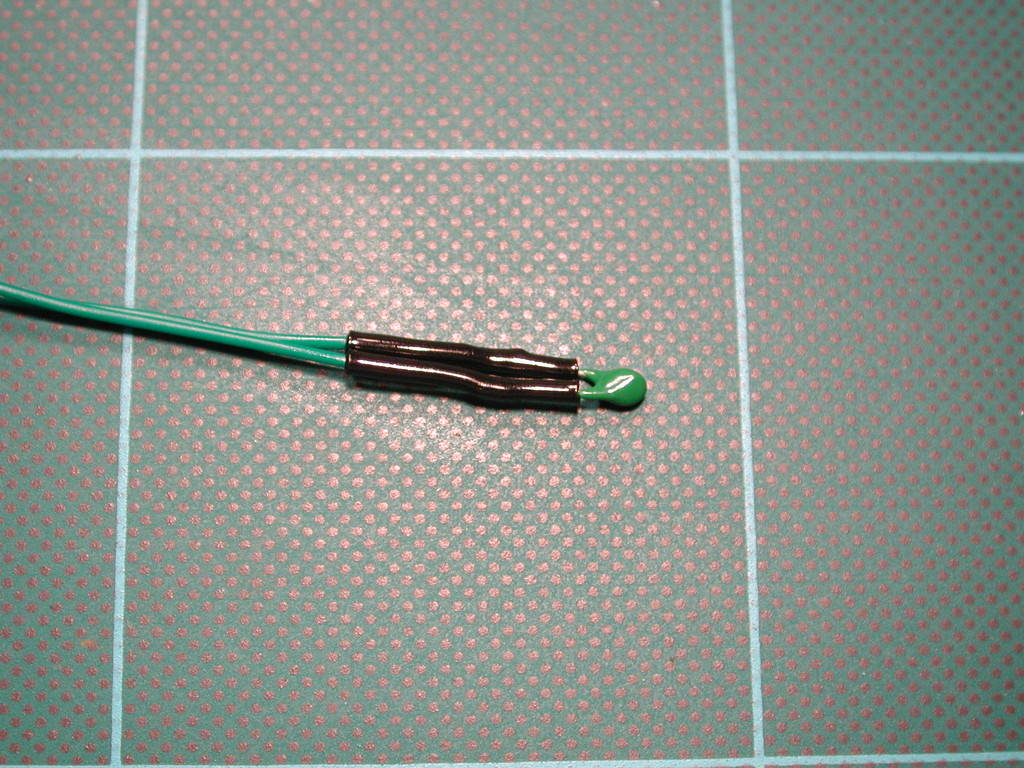

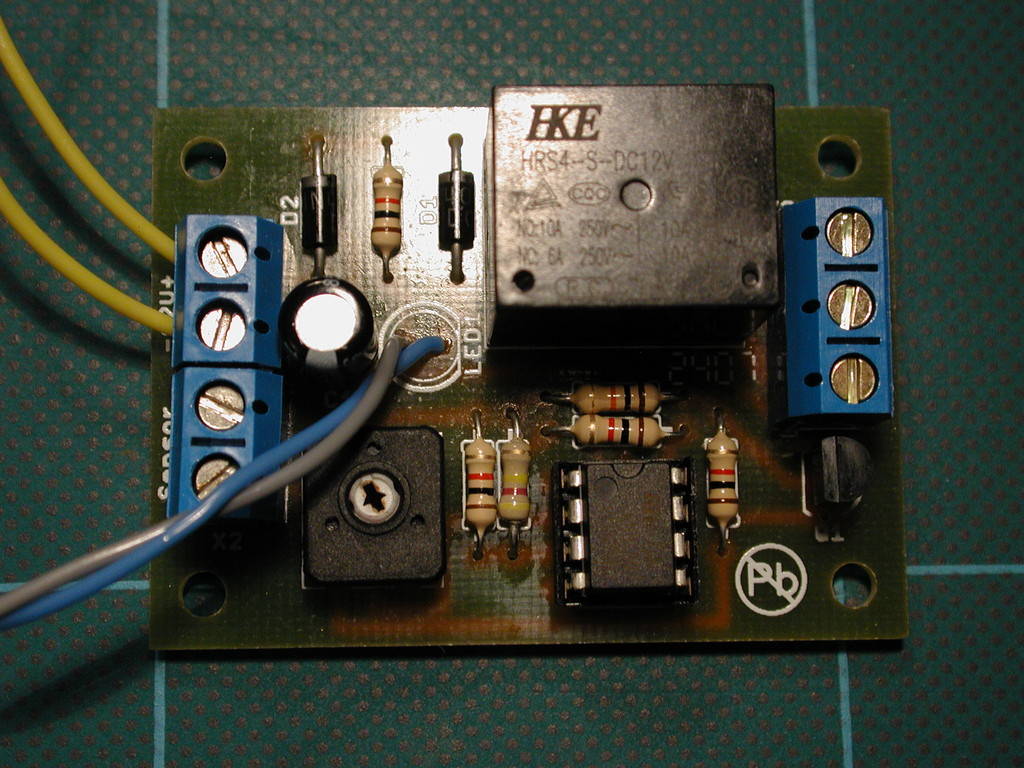

The electrical work took most of the time. I found a ready made circuit for switching the fan on/off.

It's available from Maplin as a kit but needs soldering up. The only change to the kit was the extension of the LED as

it's fixed on the side of the box to indicate when the fan is on. The design uses a relay that is triggered when the resistance

through the thermistor (sensor) drops due to temperature rise. The unit is adjustable and I set it to trigger at about

95 degrees F.

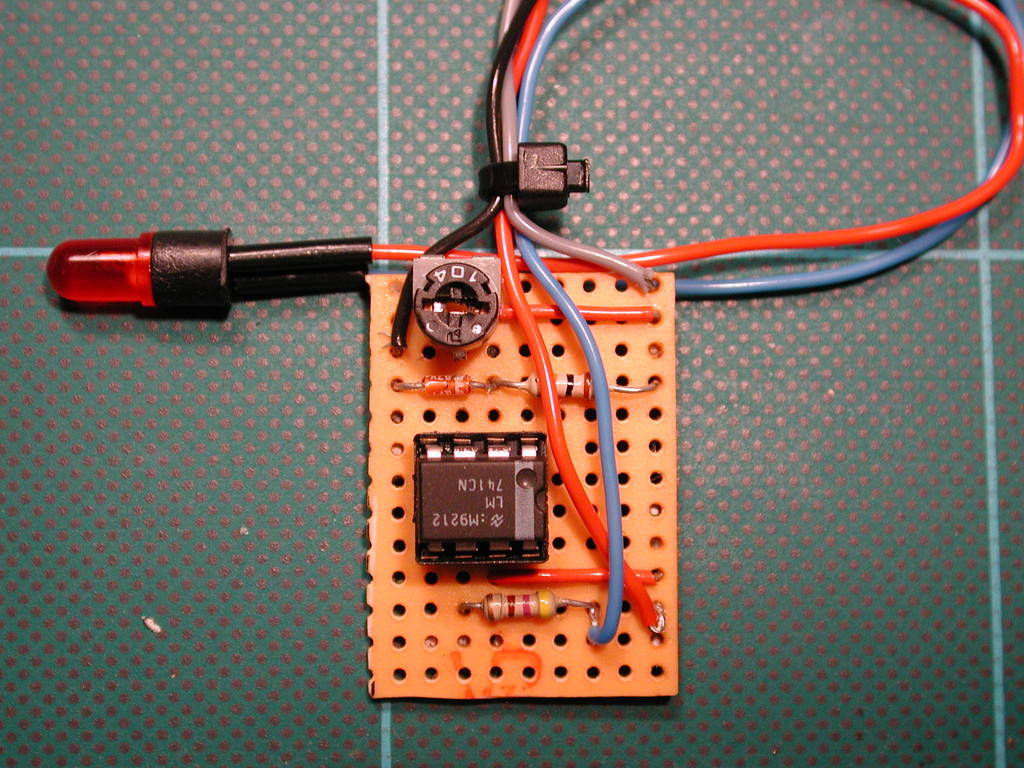

Finished temperature/relay circuit (close up)

The electrical work took most of the time. I found a ready made circuit for switching the fan on/off.

It's available from Maplin as a kit but needs soldering up. The only change to the kit was the extension of the LED as

it's fixed on the side of the box to indicate when the fan is on. The design uses a relay that is triggered when the resistance

through the thermistor (sensor) drops due to temperature rise. The unit is adjustable and I set it to trigger at about

95 degrees F.

Finished temperature/relay circuit (close up)

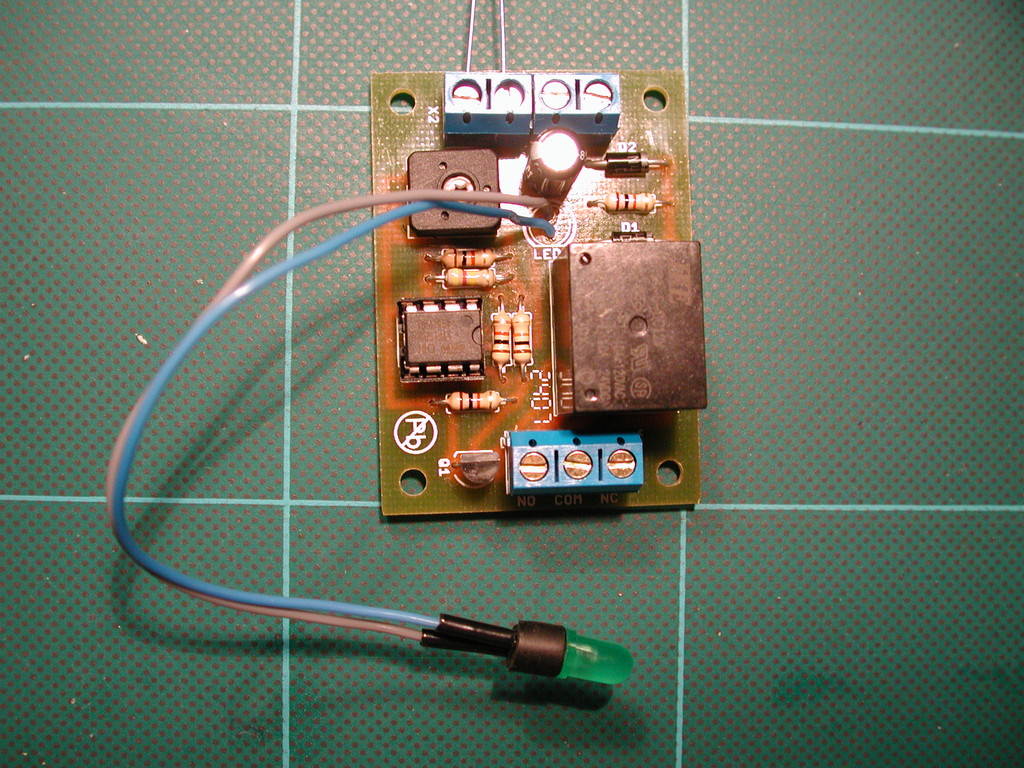

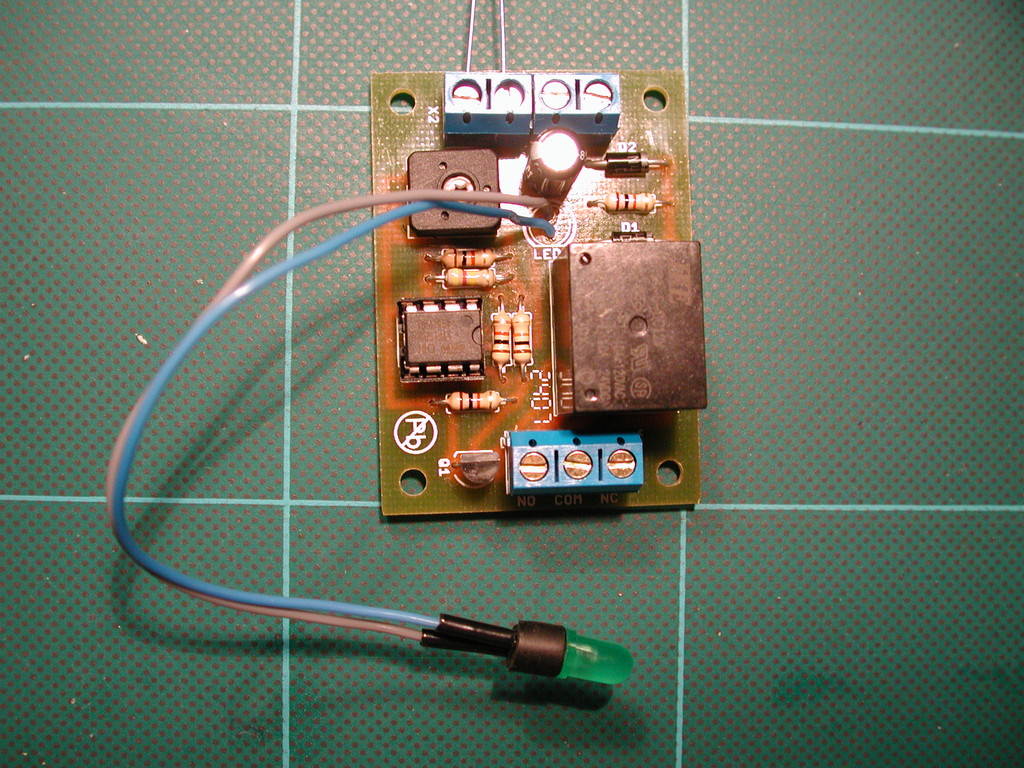

Finished temperature/relay circuit with extended LED

Finished temperature/relay circuit with extended LED

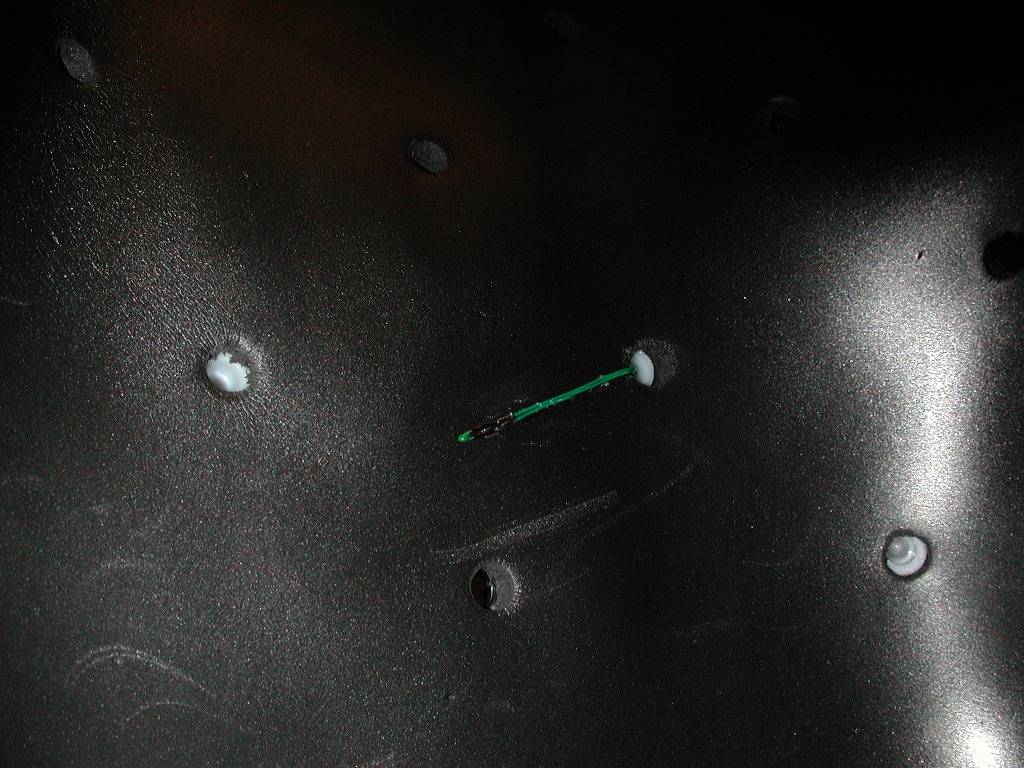

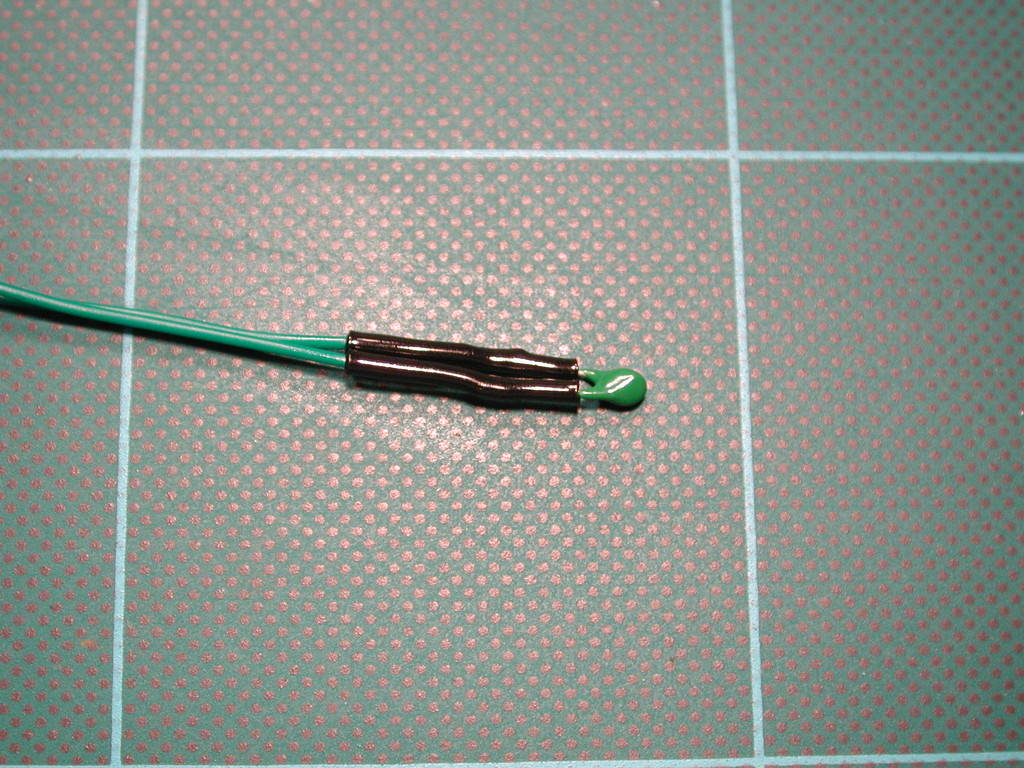

I fixed the sensor to the back of the seat and under the seat cover.

It's small enough not to be felt when sitting in the chair. The wire is fed up through a vent pipe.

I fixed the sensor to the back of the seat and under the seat cover.

It's small enough not to be felt when sitting in the chair. The wire is fed up through a vent pipe.

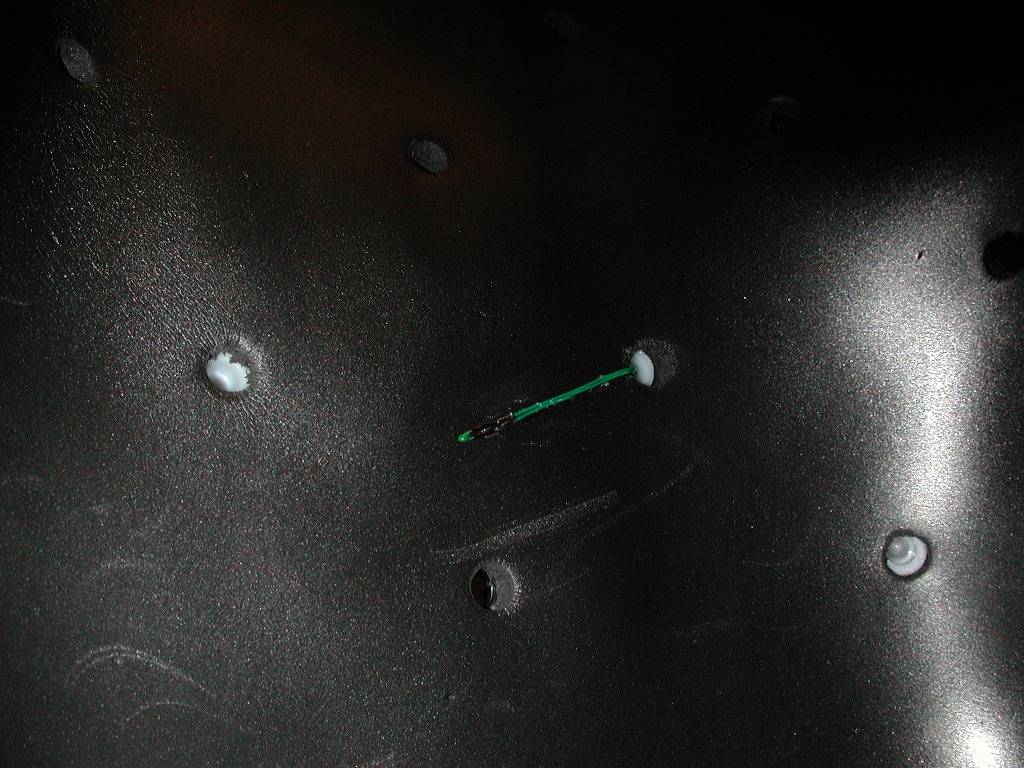

Fitted to the chair using the glue gun.

Fitted to the chair using the glue gun.

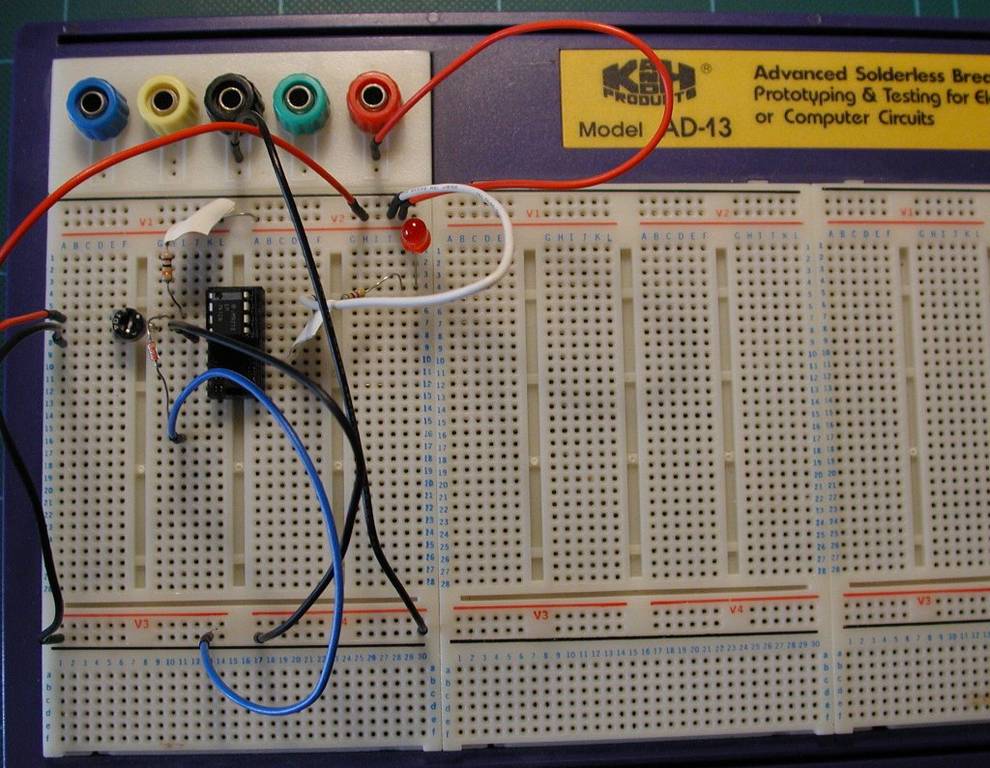

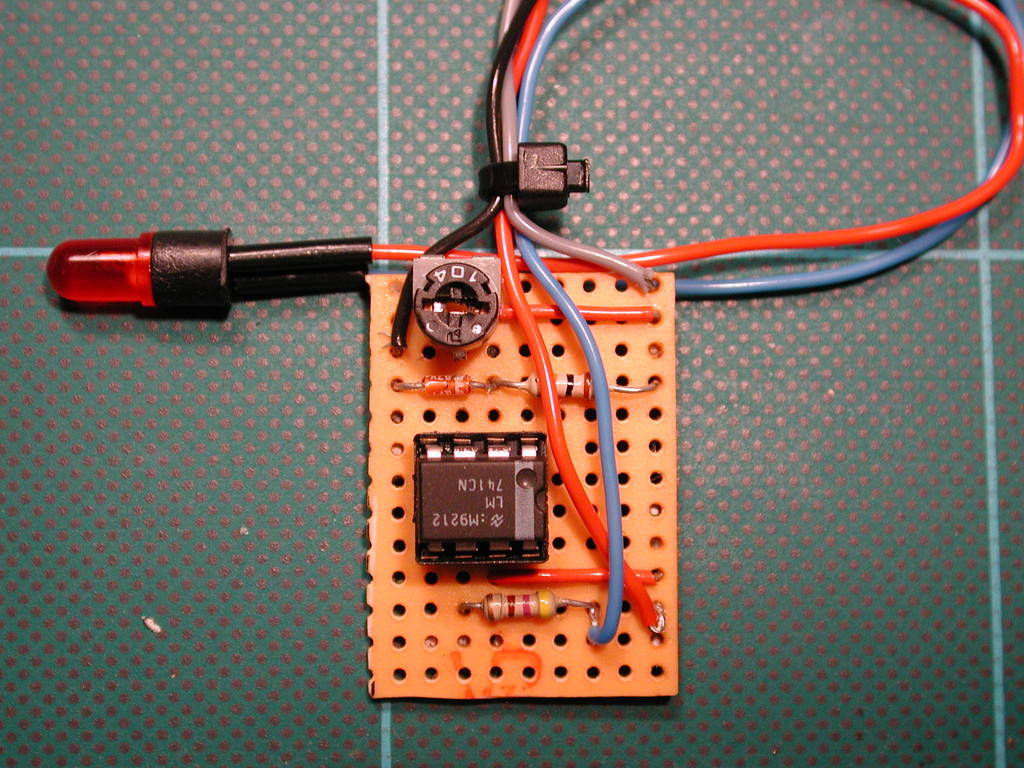

A low voltage circuit to warn of battery discharge. A simple circuit using the LM741 chip. I've set the unit to light

the LED when the voltage drops to 11.25 volts. At 11.10 volts I found that the circuit transistor is not providing sufficient

voltage/current to trigger the relay (although once running the voltage can drop to 9 volts before the relay switches off).

When the red light comes on it's time to recharge the battery.

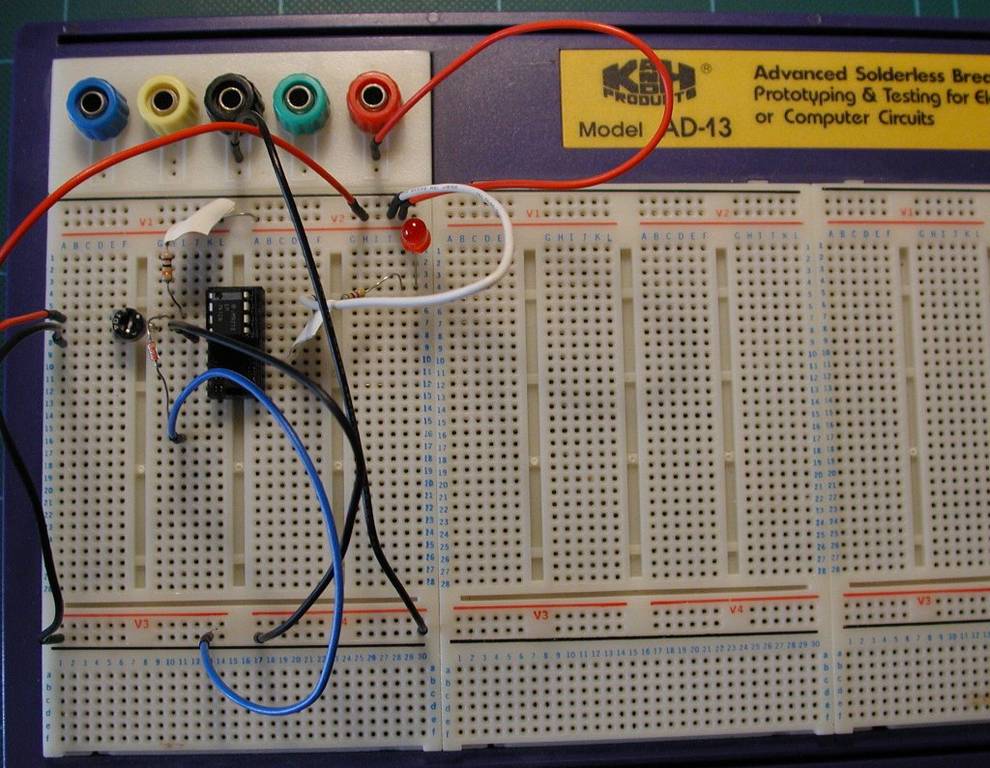

A bread board came in handy to test the low voltage circuit prior to assembly.

A low voltage circuit to warn of battery discharge. A simple circuit using the LM741 chip. I've set the unit to light

the LED when the voltage drops to 11.25 volts. At 11.10 volts I found that the circuit transistor is not providing sufficient

voltage/current to trigger the relay (although once running the voltage can drop to 9 volts before the relay switches off).

When the red light comes on it's time to recharge the battery.

A bread board came in handy to test the low voltage circuit prior to assembly.

The finished low voltage circuit.

The finished low voltage circuit.

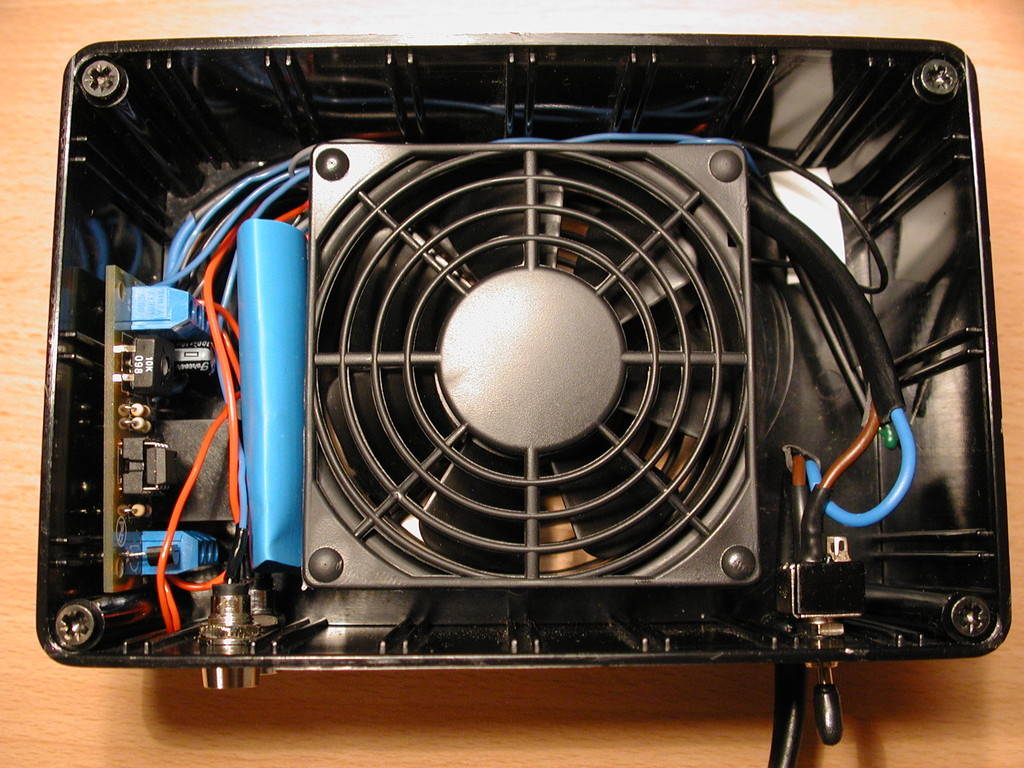

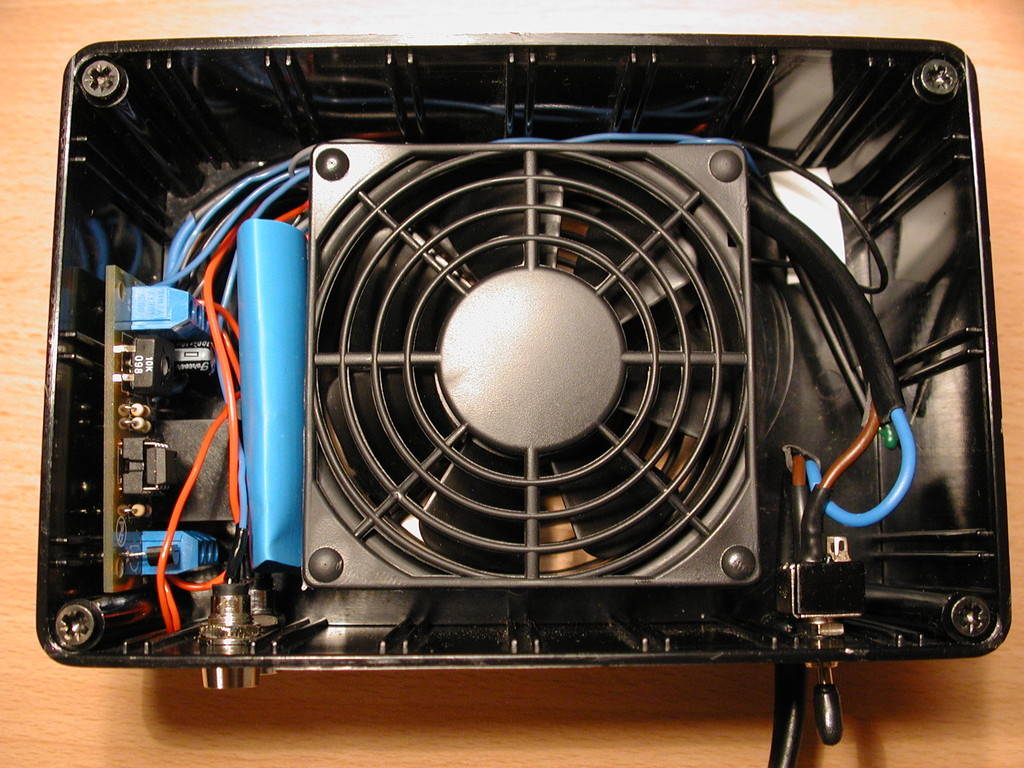

The finished air box, complete with circuits, switch, and fan. Nine holes drilled in total, 2 for led's, 1 80mm

for the PC fan, 1 for on/off switch, 1 for cable and four for the vent pipes.

The finished air box, complete with circuits, switch, and fan. Nine holes drilled in total, 2 for led's, 1 80mm

for the PC fan, 1 for on/off switch, 1 for cable and four for the vent pipes.

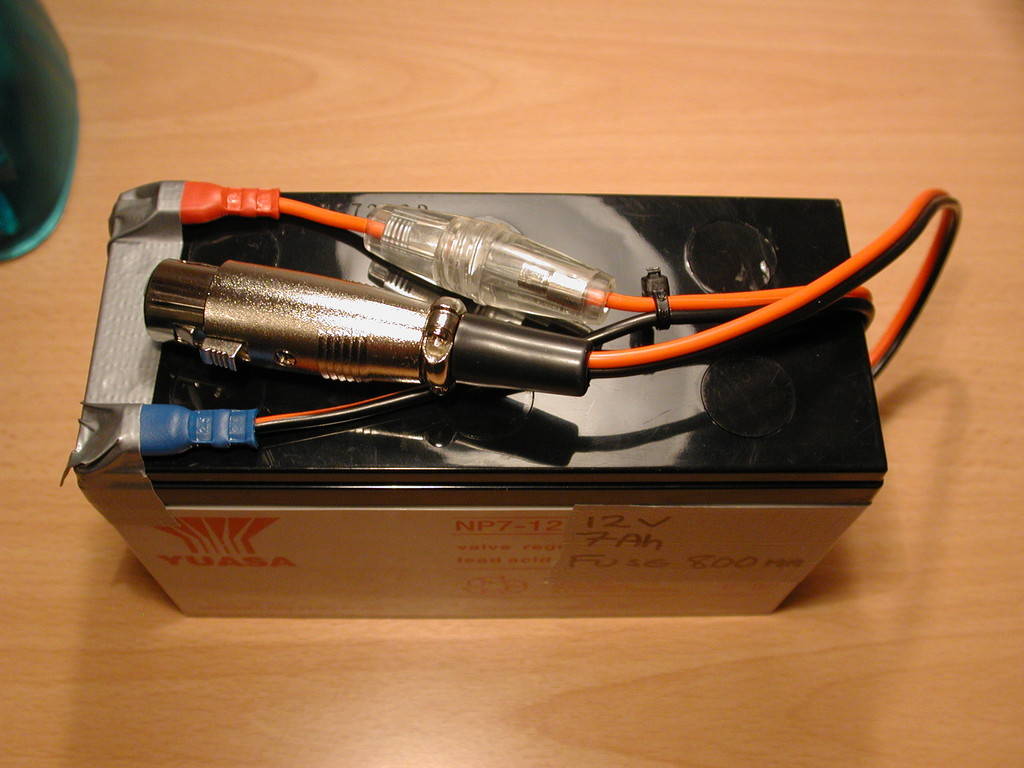

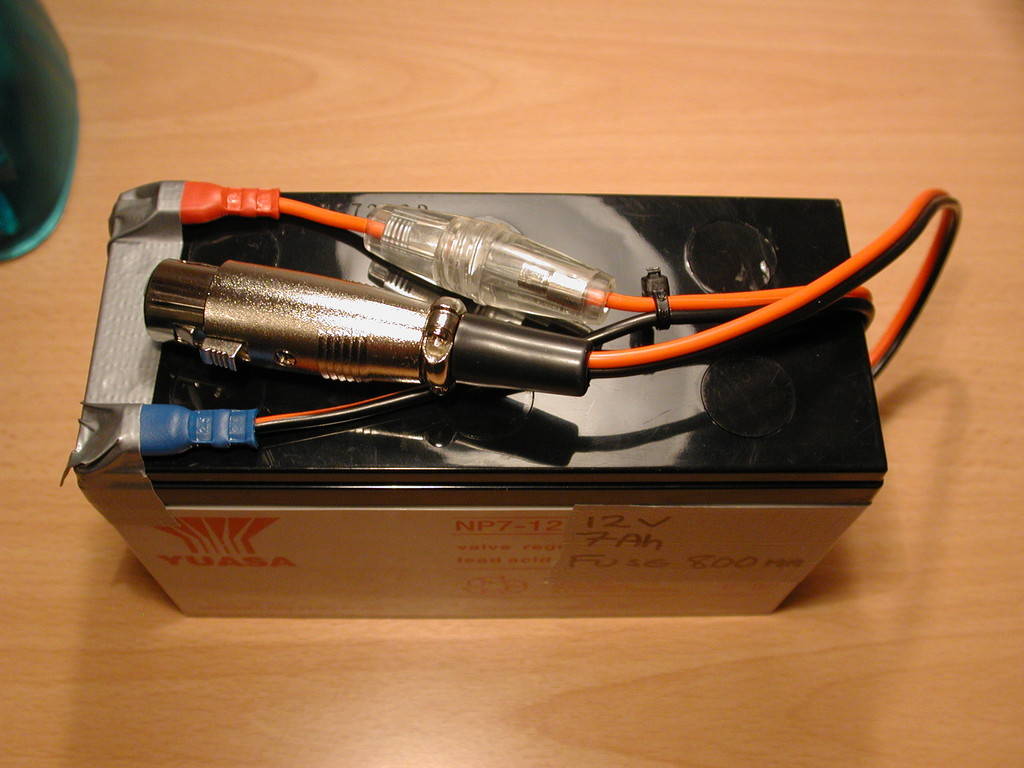

The battery a 12V 7Ah Yuasa lasts over a week based on a total current draw of 110 MA (fan, circuits and leds) and average

use of approximately 9 hours per day. I've fused the supply with a 800MA Fuse. The battery charger I use can charge at

upto 600MA so I've made allowance for this. I've used XLR

type connectors in order to make battery changes and charging easier. The battery is housed in a bag attached to the chair.

Having two batteries is a must.

The battery a 12V 7Ah Yuasa lasts over a week based on a total current draw of 110 MA (fan, circuits and leds) and average

use of approximately 9 hours per day. I've fused the supply with a 800MA Fuse. The battery charger I use can charge at

upto 600MA so I've made allowance for this. I've used XLR

type connectors in order to make battery changes and charging easier. The battery is housed in a bag attached to the chair.

Having two batteries is a must.

And the finished job (complete with stick on jewels).

And the finished job (complete with stick on jewels).

And the test pilot, although when this picture was taken a heater would have been more appropriate. We hope you

find this article useful.

And the test pilot, although when this picture was taken a heater would have been more appropriate. We hope you

find this article useful.

|

And cover removed.

And cover removed.

THE PLAN

Build a device capable of ...

a) Drawing air out of the chair.

b) Ably to run for a week (sitting time) on one battery charge.

c) Fully automatic in operation.

Initially a 12 volt fish tank air pump was a candidate but the current draw was too high.

Next, the use of a 12 volt PC fan was considered. I wasn't sure that the fan would be strong enough,

but at only 80MA current draw it was worth a try. Before starting on any electrics I rigged up the basic unit and put it on

test for a week.

Good news, no sign of over heating, everything bone dry. It would seem that a small air flow over the period of a day is enough.

True, it's not summer yet but then even indoors during winter it's been a problem, so far so good ... on with the

electrical work.

THE PARTS

Here's a list of the main components used.

a) Project Box to house the fan and electrics.

b) 80mm 12 volt PC Fan.

c) 80mm Fan Grills.

d) Circuit to switch fan on/off dependent on temperature.

e) Circuit to warn of low battery charge.

f) Flexible hose to draw air out of the chair.

g) Connectors to connect pipe to box and chair.

BUILDING

Four 20mm holes drilled in the top of the box to accommodate the pipe connectors and tubing. The box I used however will

accommodated six holes. But to start with I just used four.

THE PLAN

Build a device capable of ...

a) Drawing air out of the chair.

b) Ably to run for a week (sitting time) on one battery charge.

c) Fully automatic in operation.

Initially a 12 volt fish tank air pump was a candidate but the current draw was too high.

Next, the use of a 12 volt PC fan was considered. I wasn't sure that the fan would be strong enough,

but at only 80MA current draw it was worth a try. Before starting on any electrics I rigged up the basic unit and put it on

test for a week.

Good news, no sign of over heating, everything bone dry. It would seem that a small air flow over the period of a day is enough.

True, it's not summer yet but then even indoors during winter it's been a problem, so far so good ... on with the

electrical work.

THE PARTS

Here's a list of the main components used.

a) Project Box to house the fan and electrics.

b) 80mm 12 volt PC Fan.

c) 80mm Fan Grills.

d) Circuit to switch fan on/off dependent on temperature.

e) Circuit to warn of low battery charge.

f) Flexible hose to draw air out of the chair.

g) Connectors to connect pipe to box and chair.

BUILDING

Four 20mm holes drilled in the top of the box to accommodate the pipe connectors and tubing. The box I used however will

accommodated six holes. But to start with I just used four.

Straight Connectors

All connectors came from the aquarium shop but are probably available elsewhere. The plastic nut is used

in the average toilet cistern.

Straight Connectors

All connectors came from the aquarium shop but are probably available elsewhere. The plastic nut is used

in the average toilet cistern.

90 Degree Connectors

The vent holes already in the chair were the correct size (20mm) and the connectors screwed easily into the chair and are

surprisingly airtight.

90 Degree Connectors

The vent holes already in the chair were the correct size (20mm) and the connectors screwed easily into the chair and are

surprisingly airtight.

The electrical work took most of the time. I found a ready made circuit for switching the fan on/off.

It's available from Maplin as a kit but needs soldering up. The only change to the kit was the extension of the LED as

it's fixed on the side of the box to indicate when the fan is on. The design uses a relay that is triggered when the resistance

through the thermistor (sensor) drops due to temperature rise. The unit is adjustable and I set it to trigger at about

95 degrees F.

Finished temperature/relay circuit (close up)

The electrical work took most of the time. I found a ready made circuit for switching the fan on/off.

It's available from Maplin as a kit but needs soldering up. The only change to the kit was the extension of the LED as

it's fixed on the side of the box to indicate when the fan is on. The design uses a relay that is triggered when the resistance

through the thermistor (sensor) drops due to temperature rise. The unit is adjustable and I set it to trigger at about

95 degrees F.

Finished temperature/relay circuit (close up)

Finished temperature/relay circuit with extended LED

Finished temperature/relay circuit with extended LED

I fixed the sensor to the back of the seat and under the seat cover.

It's small enough not to be felt when sitting in the chair. The wire is fed up through a vent pipe.

I fixed the sensor to the back of the seat and under the seat cover.

It's small enough not to be felt when sitting in the chair. The wire is fed up through a vent pipe.

Fitted to the chair using the glue gun.

Fitted to the chair using the glue gun.

A low voltage circuit to warn of battery discharge. A simple circuit using the LM741 chip. I've set the unit to light

the LED when the voltage drops to 11.25 volts. At 11.10 volts I found that the circuit transistor is not providing sufficient

voltage/current to trigger the relay (although once running the voltage can drop to 9 volts before the relay switches off).

When the red light comes on it's time to recharge the battery.

A bread board came in handy to test the low voltage circuit prior to assembly.

A low voltage circuit to warn of battery discharge. A simple circuit using the LM741 chip. I've set the unit to light

the LED when the voltage drops to 11.25 volts. At 11.10 volts I found that the circuit transistor is not providing sufficient

voltage/current to trigger the relay (although once running the voltage can drop to 9 volts before the relay switches off).

When the red light comes on it's time to recharge the battery.

A bread board came in handy to test the low voltage circuit prior to assembly.

The finished low voltage circuit.

The finished low voltage circuit.

The finished air box, complete with circuits, switch, and fan. Nine holes drilled in total, 2 for led's, 1 80mm

for the PC fan, 1 for on/off switch, 1 for cable and four for the vent pipes.

The finished air box, complete with circuits, switch, and fan. Nine holes drilled in total, 2 for led's, 1 80mm

for the PC fan, 1 for on/off switch, 1 for cable and four for the vent pipes.

The battery a 12V 7Ah Yuasa lasts over a week based on a total current draw of 110 MA (fan, circuits and leds) and average

use of approximately 9 hours per day. I've fused the supply with a 800MA Fuse. The battery charger I use can charge at

upto 600MA so I've made allowance for this. I've used XLR

type connectors in order to make battery changes and charging easier. The battery is housed in a bag attached to the chair.

Having two batteries is a must.

The battery a 12V 7Ah Yuasa lasts over a week based on a total current draw of 110 MA (fan, circuits and leds) and average

use of approximately 9 hours per day. I've fused the supply with a 800MA Fuse. The battery charger I use can charge at

upto 600MA so I've made allowance for this. I've used XLR

type connectors in order to make battery changes and charging easier. The battery is housed in a bag attached to the chair.

Having two batteries is a must.

And the finished job (complete with stick on jewels).

And the finished job (complete with stick on jewels).

And the test pilot, although when this picture was taken a heater would have been more appropriate. We hope you

find this article useful.

And the test pilot, although when this picture was taken a heater would have been more appropriate. We hope you

find this article useful.